🧊 Introduction: What Are TEMA Standards in Heat Exchanger Design?

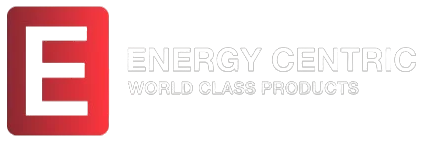

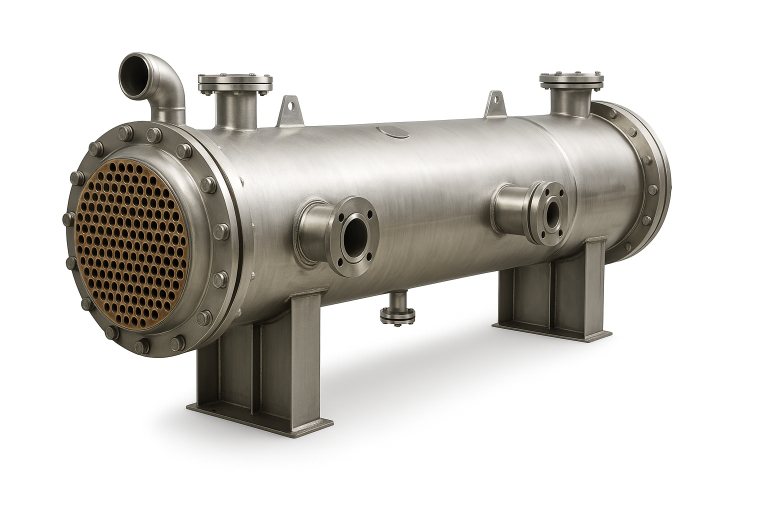

TEMA (Tubular Exchanger Manufacturers Association) standards are a set of design and construction guidelines developed specifically for shell and tube heat exchangers used in industrial applications. These standards ensure interchangeability, performance, safety, and quality across manufacturers worldwide.

Whether you’re in the chemical, oil & gas, or power generation industry, understanding TEMA classifications can help you select the right equipment for optimal performance.

🏷 What Do TEMA Standards Cover?

TEMA standards go beyond general mechanical codes like ASME. They provide detailed guidelines on:

-

Mechanical design & tolerances

-

Tube layout and construction

-

Nozzle placement and support

-

Thermal expansion allowances

-

Cleaning and maintenance access

-

Interchangeability for replacement

🧱 The Three TEMA Classes: B, C, and R

TEMA divides heat exchangers into three primary classes based on application severity:

| TEMA Class | Application | Industry Example |

|---|---|---|

| Class B | Chemical process | Petrochemical, food, general industry |

| Class C | Commercial services | HVAC, utilities |

| Class R | Refinery-grade | High pressure/high temperature oil & gas |

Class R is the most stringent in design and testing.

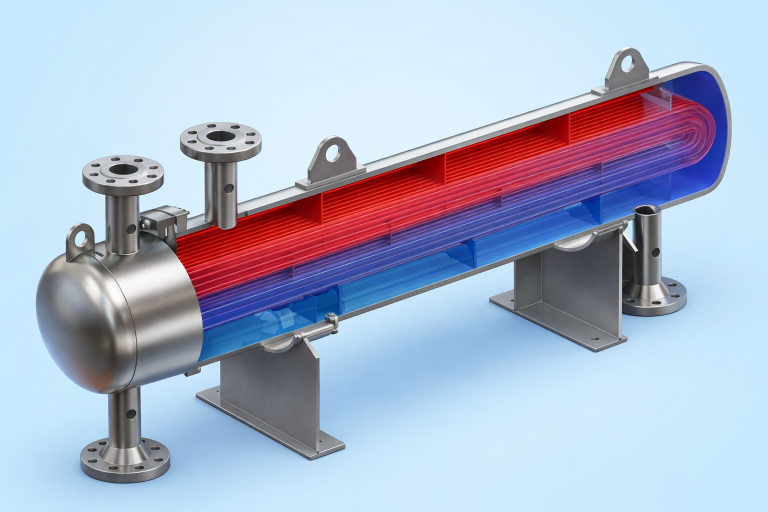

🧰 Common TEMA Types in Shell & Tube Design

TEMA also uses a three-letter code to describe heat exchanger configurations (e.g., BEM, BEU, AES), with each letter referring to:

-

Front head type

-

Shell type

-

Rear head type

Example:

BEM = Bonnet front, One-pass shell, Fixed rear cover

Choosing the right TEMA type is critical to ensuring proper thermal performance, maintenance access, and longevity.

🔎 Why TEMA Standards Matter in Heat Exchanger Design

✔ Interoperability: Easier to replace parts or units with standard sizing

✔ Compliance: Many international projects require TEMA certification

✔ Performance: Ensures consistent thermal efficiency and mechanical reliability

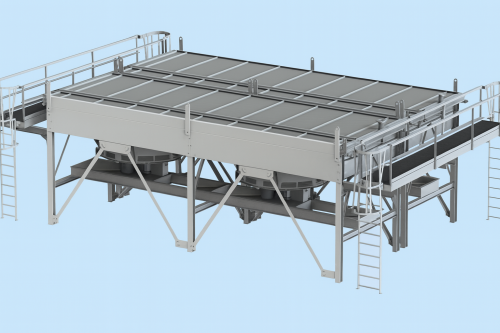

✔ Maintenance: Designs promote easy cleaning and inspection

🏭 HESCO’s Commitment to TEMA-Compliant Heat Exchangers

At HESCO, our shell & tube heat exchangers are designed and fabricated according to TEMA and ASME standards. We work closely with our clients to select the right TEMA configuration and class that aligns with their application, pressure, and temperature requirements.

🔍 Benefits of Choosing the Right TEMA Type

Selecting the proper TEMA Type for your heat exchanger doesn’t just optimize heat transfer — it also helps extend equipment lifespan, minimize maintenance downtime, and reduce long-term operational costs.

Examples:

-

If your process involves high thermal expansion, you may choose a Floating Head type (e.g., T or S) to accommodate expansion without stress.

-

For ease of cleaning and maintenance, a U-tube design (Type U) allows the tube bundle to be removed without disassembling the entire unit.

🛠 Key Considerations When Selecting a TEMA Type

-

Operating Temperature and Pressure

→ These influence mechanical design and rear head configuration. -

Maintenance Requirements

→ Some TEMA types are built for easy disassembly and frequent cleaning, while others focus on structural durability. -

Budget and Space Constraints

→ Each configuration has unique dimensions and layout implications.

🌟 Summary

TEMA standards are not just technical specifications — they are strategic tools for designing heat exchanger systems that are efficient, maintainable, and long-lasting.

At HESCO, we understand the complexity of TEMA configurations and are ready to support you with custom-designed systems that match your exact process and operating environment.

📩 Contact us: jimmy@hesco.co.th

📞 Phone: +66 983282941