🛠️ What Is the ASME Standard? Why It Matters for Heat Exchangers and Pressure Vessels

ASME, or the American Society of Mechanical Engineers, is one of the most widely recognized organizations in the world for setting engineering codes and standards. Its most important publication is the ASME Boiler and Pressure Vessel Code (BPVC) — a globally adopted guideline for the design, fabrication, and inspection of pressure-retaining equipment.

For industries that rely on heat exchangers, pressure vessels, and boilers, ASME compliance is not only a legal requirement in many countries but also a seal of safety, reliability, and international credibility.

✅ What Is ASME Section VIII, Division 1?

ASME Standard

ASME Section VIII, Division 1 governs the design and fabrication of pressure vessels that operate under internal or external pressure exceeding 15 psi (1 bar). It is the most commonly applied division in industrial applications due to its versatility and comprehensive scope.

Key elements include:

-

Wall thickness calculations based on pressure and temperature

-

Material selection and traceability

-

Stress analysis and corrosion allowances

-

Non-destructive testing (NDT) such as radiographic, ultrasonic, or dye penetrant inspection

-

Hydrostatic or pneumatic pressure testing

-

Nameplate stamping and documentation

📘 ASME Standards and Heat Exchanger Applications

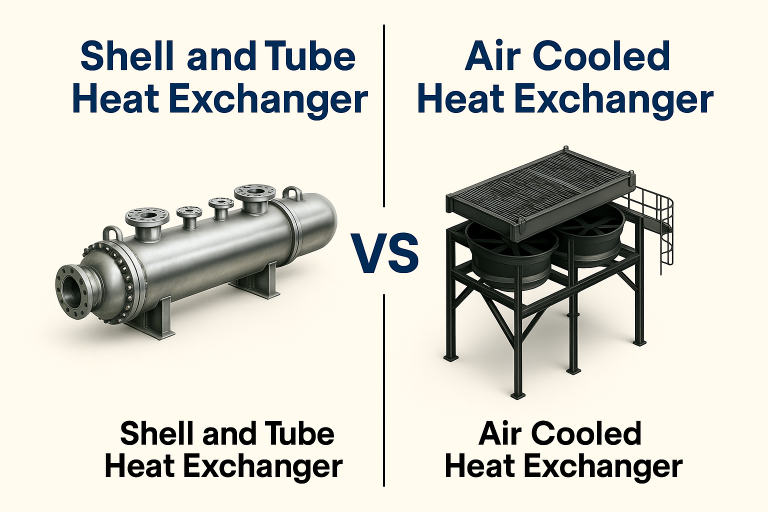

| Type of Heat Exchanger | ASME Requirement? | Notes |

|---|---|---|

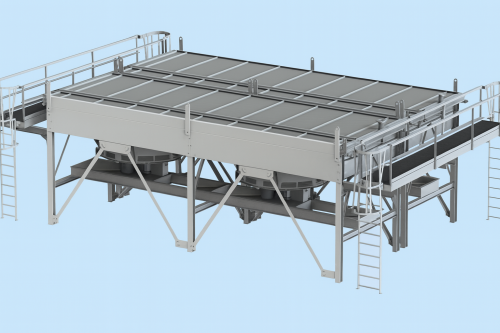

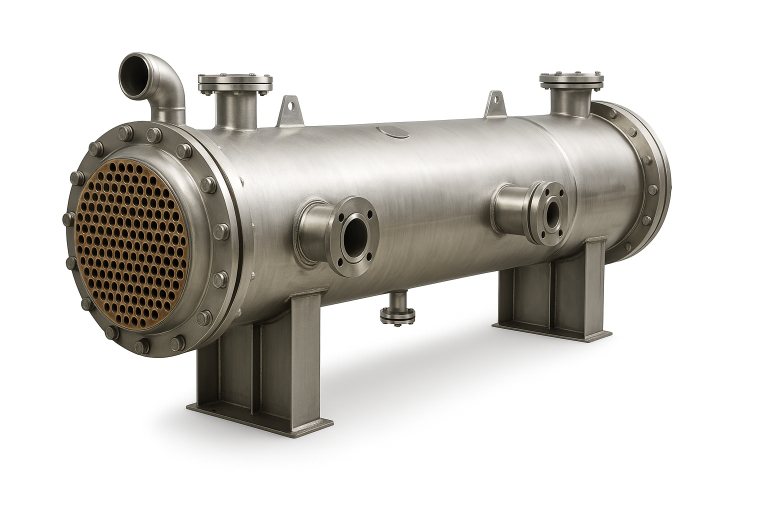

| Shell & Tube Heat Exchanger | ✅ Yes | Considered a pressure vessel; must meet Section VIII |

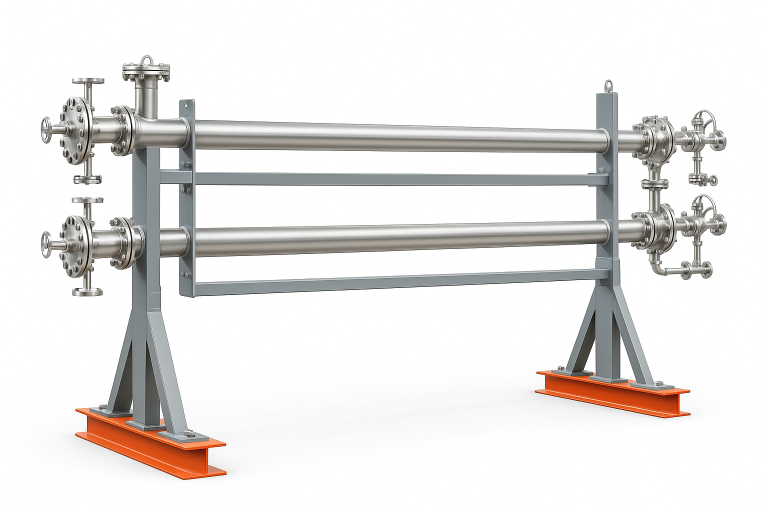

| Air Cooled Heat Exchanger | ✅ Partially | Header box, piping, and manifolds must comply |

| Plate Heat Exchanger | ❌ Not always | Applies only if pressure exceeds design thresholds |

🔍 Why Use ASME-Certified Equipment?

-

Maximum Safety

Ensures equipment won’t fail under expected operating pressure and temperature. -

Global Acceptance

Many international EPCs (Engineering, Procurement, Construction) require ASME-certified components. -

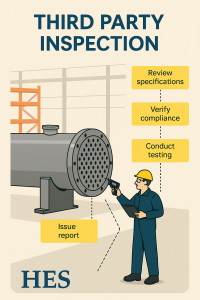

Easier Third-Party Inspection (TPI)

ASME-stamped items simplify approval by independent inspectors and insurance providers. -

Extended Equipment Life

Proper material selection, corrosion allowance, and stress limits lead to longer service life. -

Project Approval in High-Compliance Industries

Essential for oil & gas, petrochemical, power generation, LNG, and refinery projects.

🏭 ASME Compliance at HESCO-Thailand

At HESCO-Thailand, we fabricate all Shell & Tube Heat Exchangers, Air Cooled Heat Exchangers, and Pressure Vessels under full compliance with ASME Section VIII, Division 1.

Our capabilities include:

-

In-house thermal and mechanical design by licensed engineers

-

Certified welding procedures (WPS/PQR/WPQ)

-

100% NDT and hydrotest according to ASME code

-

Material traceability with MTRs and ASME-compliant documentation

-

Third-party inspections (Lloyd’s, Bureau Veritas, DNV, etc.) upon request

We do not outsource — every piece is designed, built, and tested in Thailand by our team.

🔧 Additional ASME-Related Services by HESCO

-

Re-rating and modification of pressure vessels

-

Heat exchanger code calculations (PVElite, HTRI)

-

ASME nameplate registration and stamping

-

API 661 for air-cooled heat exchangers

-

TEMA standards integration for shell & tube designs

🔗 Suggested

1.How to Select a Heat Exchanger for Your Application https://www.energycentric.co.th/how-to-select-a-heat-exchanger-for-your-application/ 2.Air Cooled Heat Exchanger (Fin Fan) for Industrial Use https://www.energycentric.co.th/air-cooled-heat-exchanger-fin-fan-for-industrial-use/ 3.The American Society of Mechanical Engineers https://www.asme.org/

Consult With an ASME-Ready Manufacturer

Looking for a trusted partner for pressure-rated heat exchangers and vessels?

Contact HESCO-Thailand today for consultation, technical proposal, or RFQ.

📧 Email: jimmy@hesco.co.th

📞 Phone: +66 983282941