A pressure vessel contains gases or liquids at a pressure significantly different from the surrounding atmosphere. Industries such as oil & gas, petrochemical, power generation, and food processing rely on these vessels for critical operations.

To ensure safety, engineers design, manufacture, and test pressure vessels according to strict standards like ASME Section VIII.

🏭 Applications of Pressure Vessels

Many industries use pressure vessels, including:

- Oil & Gas: Stores compressed gases, separates phases, and transfers heat.

- Chemical Processing: Serves as reactors and distillation columns.

- Power Plants: Operates in boilers and steam drums.

- Food & Beverage: Pressurizes tanks for fermentation or carbonation.

- Pharmaceutical: Maintains sterile conditions in controlled vessels.

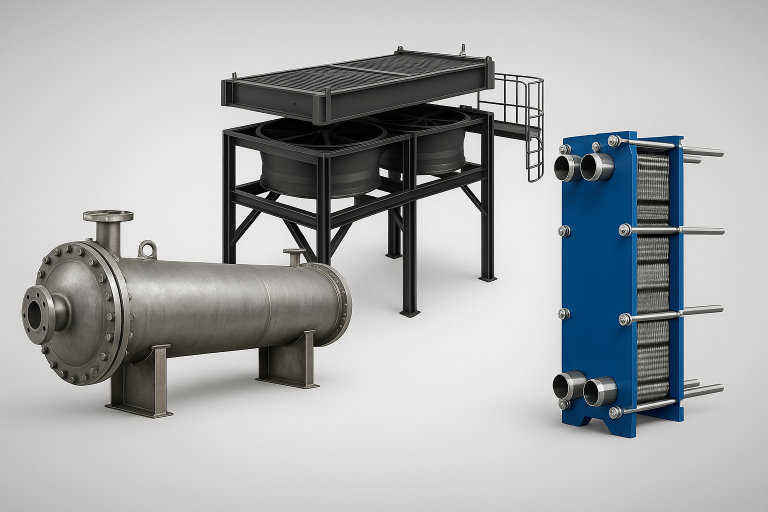

🔍 Common Types of Pressure Vessels

| Type | Description |

|---|---|

| Horizontal & Vertical Vessels | Aligns orientation to space or process requirements |

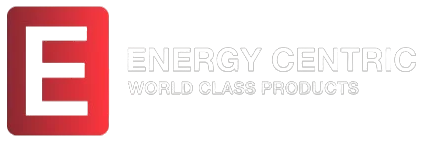

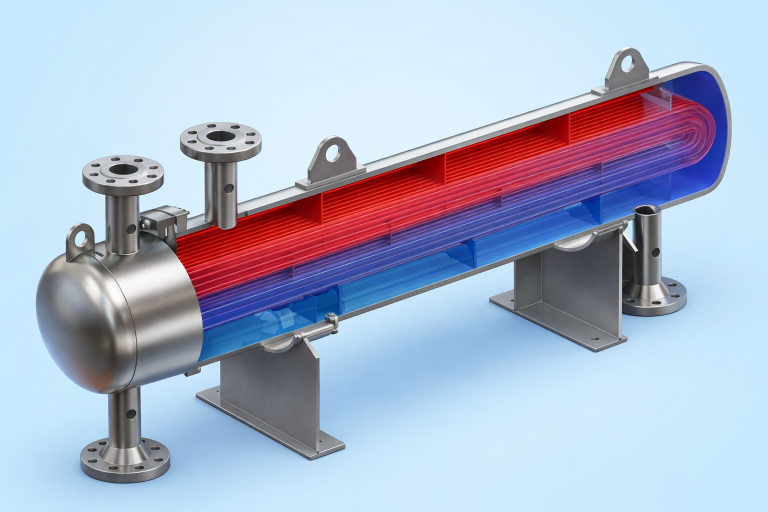

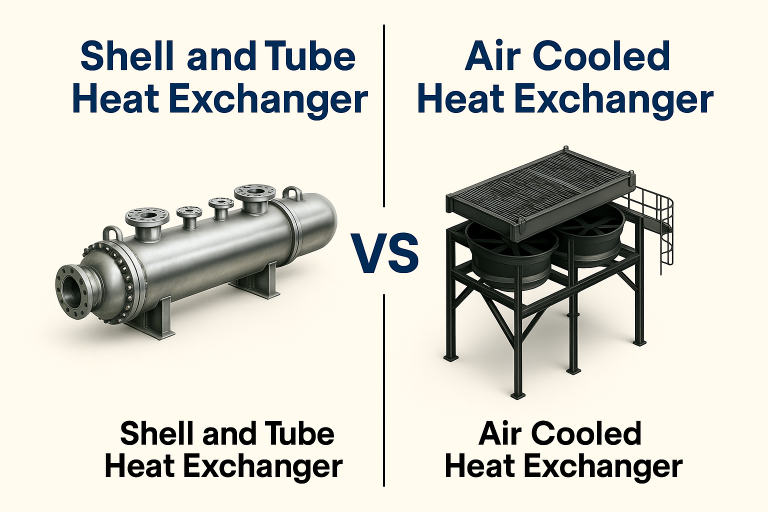

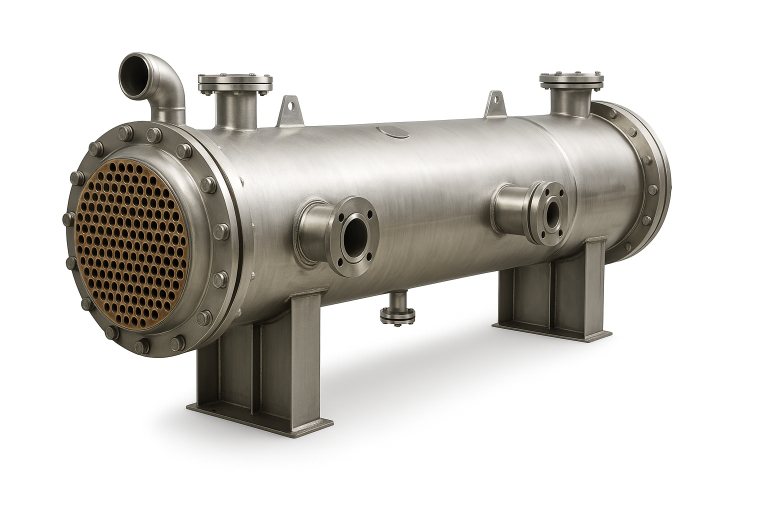

| Heat Exchangers | Transfers heat under pressure, including shell and tube types |

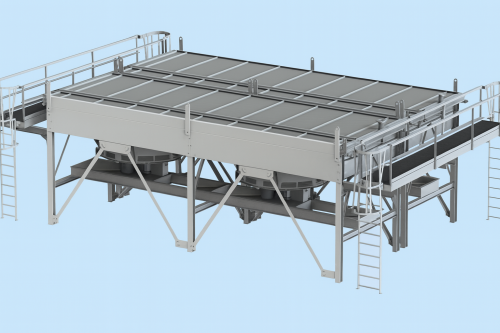

| Columns & Towers | Performs distillation, absorption, and separation |

| Storage Tanks | Holds liquids, vapors, or gases under pressure |

⚙️ Key Design Considerations

Engineers evaluate several key factors to design pressure vessels:

- Internal and External Pressure

- Operating Temperature

- Material Selection: Carbon steel, stainless steel, or exotic alloys

- Corrosion Allowance & Protective Lining

- Welding Methods & Non-Destructive Testing (NDT)

- Design Codes: ASME, PED, TEMA, etc.

🛡️ Why ASME Standard Matters

ASME Section VIII ensures:

- Structural integrity under pressure

- Standardized manufacturing practices

- Reliable safety performance

- Global export readiness

Authorized third-party inspectors verify and certify vessels with the ASME U-Stamp, ensuring compliance with international codes.

🔧 HESCO’s Expertise in Pressure Vessel Fabrication

HESCO-Thailand designs and fabricates pressure vessels to meet ASME standards. Our in-house engineering team uses PV Elite and Compress for accurate code calculations. We also coordinate with certified third-party inspectors to guarantee 100% compliance and readiness for export.

We deliver:

- ASME Section VIII Division 1 vessels

- Code stamping (U, R, NB)

- Complete material traceability and certifications

- Hydrotesting and third-party inspection services

- Vessel re-rating and modifications

📈 Optimize Performance & Safety with HESCO

Choose a pressure vessel from HESCO to:

✅ Maximize safety standards

✅ Comply with global regulations

✅ Ensure long-term reliability

✅ Customize to your process needs

📩 Contact Us Today

Let HESCO help you select or design a pressure vessel that suits your needs.

📩 Email: jimmy@hesco.co.th

📞 Phone: +66 983282941