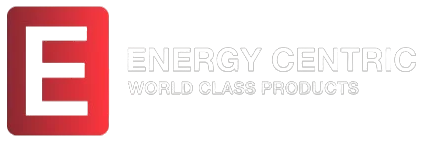

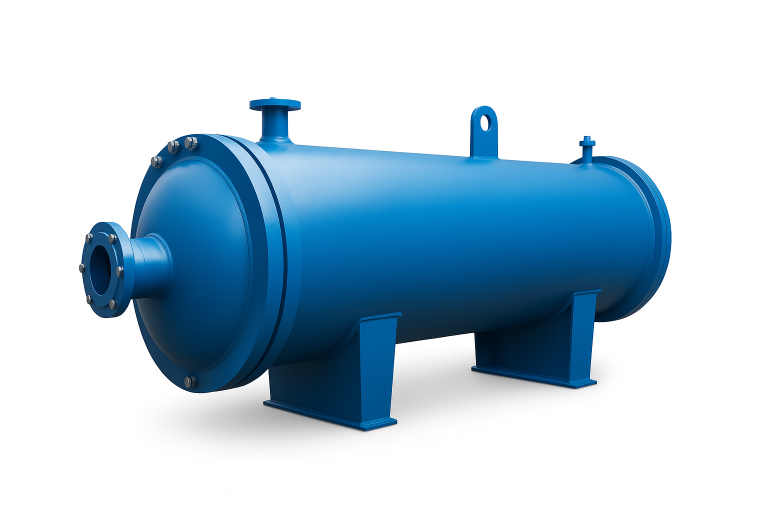

A Shell and Tube Heat Exchanger is one of the most commonly used heat exchanger types in industrial applications. Thanks to its robust structure and design flexibility, it is widely used in oil refineries, power plants, chemical processing facilities, and HVAC systems.

🧱 Basic Structure

Fundamentally, the exchanger consists of two main sections:

- Shell – the outer cylindrical vessel containing one process fluid.

- Tubes – a bundle of smaller tubes through which the second fluid flows.

Importantly, one fluid travels through the tubes, while the other circulates around them within the shell. This arrangement allows efficient heat transfer between the two fluids without direct contact.

🔄 Step-by-Step Working Principle

To understand its operation more clearly, let’s walk through the process:

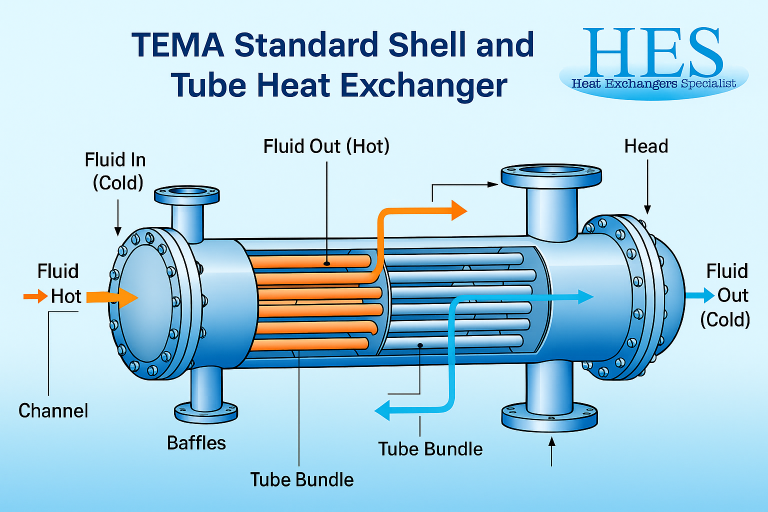

🔸 Step 1: Fluid Entry

First, the hot or cold process fluid enters the tube side via an inlet nozzle and flows through the tube bundle.

Simultaneously, the second fluid enters the shell side, flowing around the outside of the tubes.

🔸 Step 2: Heat Exchange

Then, heat transfers through the tube walls as the two fluids move in opposite directions (in counterflow or crossflow configurations).

As a result, one fluid releases heat while the other absorbs it.

🔸 Step 3: Fluid Exit

Finally, after heat exchange, both fluids exit through their respective outlet nozzles.

Additionally, baffles installed in the shell enhance heat transfer by increasing turbulence and improving flow distribution.

🔍 Key Benefits

Clearly, shell and tube heat exchangers offer several advantages:

👉 Suitable for high-pressure and high-temperature applications

👉 Easy to clean, inspect, and maintain

👉 Capable of handling phase changes such as condensation and boiling

👉 Adaptable to multiple configurations like fixed tube, U-tube, or floating head

🛠️ Types of Shell and Tube Heat Exchangers

Depending on the operating conditions, engineers can select from various designs:

🔹 Fixed Tube Sheet

- Simple and cost-effective

- Ideal for clean, non-corrosive fluids

- Tubes are permanently welded to the sheet

🔹 U-Tube Design

- Features a curved tube bundle

- Accommodates thermal expansion

- Requires only one tube sheet

🔹 Floating Head

- One end is free to move

- Facilitates easy cleaning and maintenance

- Best suited for fouling or corrosive environments

🔎 Thermal Design Considerations

In order to ensure optimal performance, engineers evaluate several key parameters:

- Log Mean Temperature Difference (LMTD) – maintains a sufficient temperature gradient

- Overall Heat Transfer Coefficient (U-value) – affects exchanger sizing and efficiency

- Tube Pitch and Layout – triangle pitch offers compactness, while square pitch allows better cleaning

- Flow Patterns – counterflow offers the highest thermal efficiency, while crossflow balances pressure drop

🌍 Environmental and Economic Advantages

Moreover, these exchangers support sustainability and cost-efficiency:

\267b️ Recover waste heat from industrial operations

💧 Reduce water usage through closed-loop circulation

🔧 Lower maintenance costs due to durable design

🌱 Align with environmental regulations and efficiency standards

🪰 Optional Enhancements

To further improve performance, engineers can integrate:

- Turbulence-inducing tube inserts

- Corrosion-resistant materials like stainless steel or titanium

- Expansion joints for thermal stress relief

- Monitoring instruments such as pressure gauges and thermocouples

🏣 Common Applications

In conclusion, shell and tube heat exchangers are ideal for:

- Petrochemical and oil & gas processing

- Steam generation and condensing systems

- Power plant turbines

- Refrigeration and air conditioning systems

📩 Contact Us Today

Need help selecting or designing a pressure vessel for your application?

📩 Email: jimmy@hesco.co.th

📞 Phone: +66 983282941