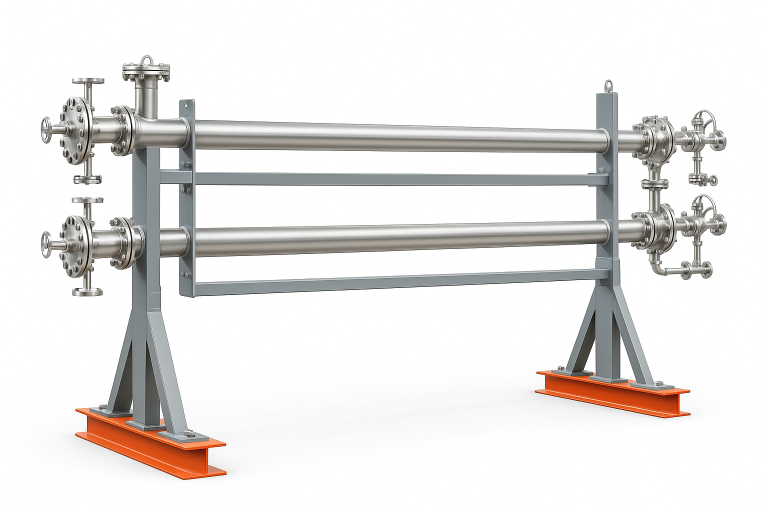

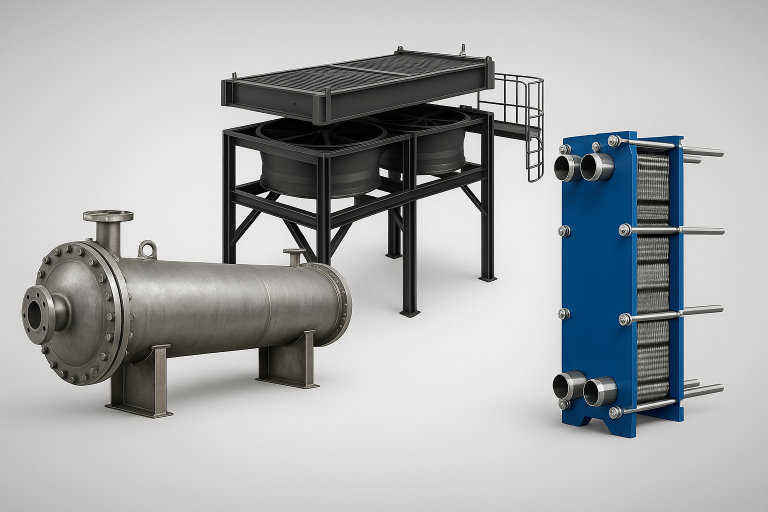

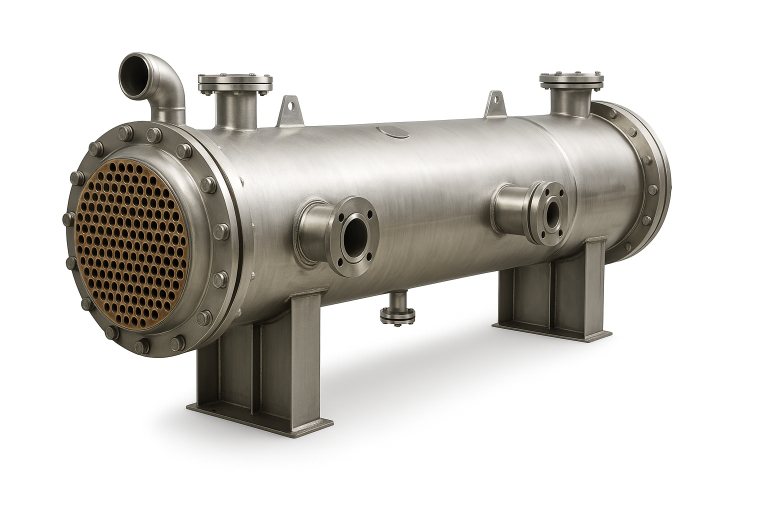

What Is a Shell and Tube Heat Exchanger?

A Shell and Tube Heat Exchanger is a type of heat exchanger commonly used in industrial applications. It consists of a cylindrical shell (outer body) and a bundle of tubes inside. One fluid flows through the tubes, and another fluid flows outside the tubes (within the shell), allowing for efficient heat transfer between the two without direct contact.

🧱 Basic Structure

-

Shell: The outer cylindrical container that holds one of the process fluids.

-

Tubes: A series of metal tubes inside the shell where the second fluid flows.

-

Tube Sheet: Plates that hold the tubes in place at both ends.

-

Baffles: Plates inside the shell that direct fluid flow, increase turbulence, and improve heat transfer.

🔄 How It Works

-

Fluid Entry

-

One fluid enters the tube side via an inlet nozzle.

-

The second fluid enters the shell side, flowing around the tubes.

-

-

Heat Exchange

-

Heat is transferred from the hotter fluid to the cooler one through the tube walls via conduction and convection.

-

-

Fluid Exit

-

After heat exchange, both fluids exit through separate outlets.

-

⚙️ Types of Shell and Tube Designs

-

Fixed Tube Sheet: Simple, cost-effective, ideal for clean fluids.

-

U-Tube Design: Allows thermal expansion; tubes are bent into a U-shape.

-

Floating Head: One end of the tube bundle is free to expand, making it easier to clean and suitable for fouling fluids.

✅ Advantages

-

High-pressure and high-temperature capacity

-

Easy maintenance and cleaning

-

Long service life

-

Capable of handling phase change (e.g., boiling, condensation)

-

Flexible design options

🏭 Common Applications

-

Petrochemical plants

-

Power generation (steam condensers)

-

HVAC systems

-

Oil and gas refineries

-

Food processing

🌍 Material Selection

-

Carbon Steel: General-purpose applications

-

Stainless Steel: Corrosion resistance

-

Titanium / Copper Alloys: High conductivity or corrosive environments

📏 Design Standards

Shell and Tube Heat Exchangers are often built to meet industry standards such as:

-

TEMA (Tubular Exchanger Manufacturers Association)

-

ASME Section VIII (for pressure vessels)

-

API 660 (Petroleum applications)

📌 Summary

Shell and Tube Heat Exchangers offer a proven, robust solution for transferring heat efficiently in demanding industrial settings. Their flexibility, reliability, and adaptability make them a top choice across various sectors.

Suggested

Suggested

1.Shell and Tube Heat Exchanger

https://www.energycentric.co.th/introduction-to-shell-and-tube-heat-exchangers/

2.How to Select a Heat Exchanger

https://www.energycentric.co.th/how-to-select-a-heat-exchanger-for-your-application/

📩 Contact HESCO‑Thailand for Shell and Tube Heat Exchangers

Email: jimmy@hesco.co.th

Phone: +66 983282941