✅ Overview

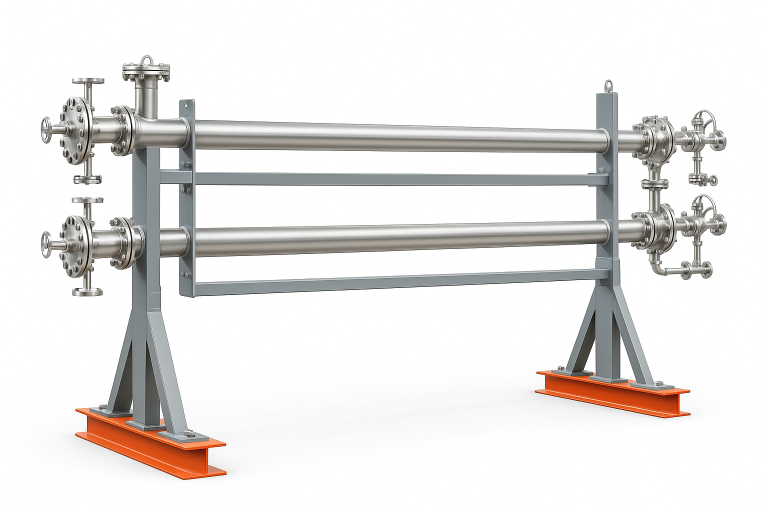

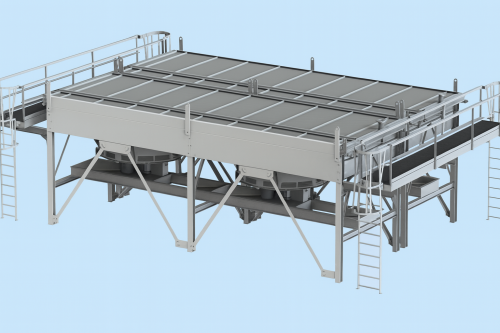

An Air Cooled Heat Exchanger (ACHE) or Fin Fan is a type of industrial heat exchanger that uses ambient air to remove heat from process fluids. Unlike traditional water-cooled systems, ACHEs eliminate the need for cooling towers, water treatment systems, and large volumes of water — making them eco-friendly, efficient, and ideal for remote or arid environments.

They are widely used in refineries, petrochemical plants, power plants, natural gas processing units, and other industries where process fluid cooling is essential.

🔧 Air cooled heat exchanger (Fin Fan) working principle

Air Cooled Heat Exchangers rely on forced convection to transfer heat from hot process fluid to ambient air. Let’s break down how this process works:

🔸 Step 1: Process Fluid Entry

Hot fluid flows into the header box and enters the finned tubes inside the heat exchanger.

🔸 Step 2: Heat Transfer Mechanism

The finned tubes increase the surface area, allowing more heat to escape. As the fluid moves through the tubes, fans drive ambient air across the fins. This air absorbs the heat through convection.

🔸 Step 3: Air Flow Types

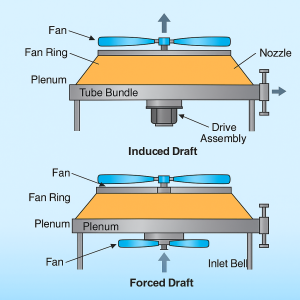

There are two common configurations:

-

In a forced draft setup, fans sit beneath the tube bundle and push air upward through the fins.

-

In an induced draft design, fans mount above the bundle and pull air through from below.

Induced draft systems offer better cooling efficiency, while forced draft systems simplify maintenance access.

🔸 Step 4: Fluid Exit

After releasing its heat, the fluid exits the tubes at a lower temperature and returns to the process loop.

🧩 Key Components and Their Functions

| Component | Function |

|---|---|

| Finned Tubes | Enhance heat transfer by increasing external surface area |

| Header Box | Distributes fluid uniformly into tubes |

| Fans (axial) | Move ambient air across the tube bundle |

| Plenum Chamber | Directs airflow evenly and reduces turbulence |

| Drive System | Powers the fans (electric motor or belt-driven) |

| Vibration Dampers | Reduce mechanical stress during operation |

| Control Panel | Manages fan speed, temperature, alarms, etc. |

📈 Thermal and Mechanical Design Considerations

Designing an efficient ACHE requires careful analysis of the following parameters:

-

Ambient Air Conditions

-

Temperature, humidity, altitude, wind speed

-

Seasonal variations for minimum/maximum cooling performance

-

-

Heat Load

-

Duty (kW), fluid type, flow rate, inlet/outlet temperature

-

-

Tube and Fin Material

-

Common: Carbon steel, stainless steel, aluminum, copper-nickel

-

Corrosion resistance vs thermal conductivity trade-off

-

-

Noise & Vibration

-

Fans can generate noise levels of 85–100 dB

-

Acoustic louvers and dampers may be required in sensitive environments

-

-

Redundancy & Maintenance Access

-

Multiple fans or bundles to allow partial operation during maintenance

-

Walkways, ladders, and platforms for service crews

-

💡 ACHE vs Water-Cooled Systems

| Factor | Air Cooled | Water Cooled |

|---|---|---|

| Water Usage | None | High |

| Maintenance | Lower | Higher (scaling, fouling) |

| Initial Cost | Higher | Lower |

| Operating Cost | Lower | Higher (water treatment, disposal) |

| Footprint | Larger | Smaller |

| Environmental Impact | Minimal | Water discharge concerns |

🏭 Why Choose HESCO-Thailand for Air Cooled Heat Exchangers?

At HESCO-Thailand, we are proud to be the only fabricator in Thailand that offers both thermal and mechanical design in-house for Air Cooled Heat Exchangers (ACHE). From concept to fabrication, we control every aspect to ensure efficiency, durability, and precise performance for your application.

We don’t rely on overseas engineering — we design, build, and test right here in Thailand.

👥 Trusted by Leading Industry Players

Our expertise is trusted by top-tier clients across multiple sectors, including:

-

Bangchak Corporation

-

ThyssenKrupp

-

TTCL

-

IRPC

-

…and many more across energy, petrochemical, and infrastructure sectors.

🔗 Suggested

-

TEMA – Tubular Exchanger Manufacturers Association

“Learn more about design standards from the official TEMA organization.” -

ASME Boiler and Pressure Vessel Code (BPVC)

“See how air cooled heat exchangers often follow ASME Section VIII guidelines.” -

API 661 Standard – Air-Cooled Heat Exchangers for General Refinery Services

“API 661 provides specifications commonly used in refinery-grade air cooled exchangers.” -

Energy Efficiency – U.S. Department of Energy

“Explore how heat exchangers improve energy efficiency in industrial systems.” -

What is a Heat Exchanger – Engineering Toolbox

“A general overview of different types of heat exchangers and how they function.”

📞 Let’s Talk Cooling

Ready to design a system that saves water, energy, and maintenance costs?

👉 Contact HESCO for a consultation or to request a quote today.

📩 Email: jimmy@hesco.co.th

📞 Phone: +66 983282941