Shell and Tube vs Air Cooled Heat Exchanger

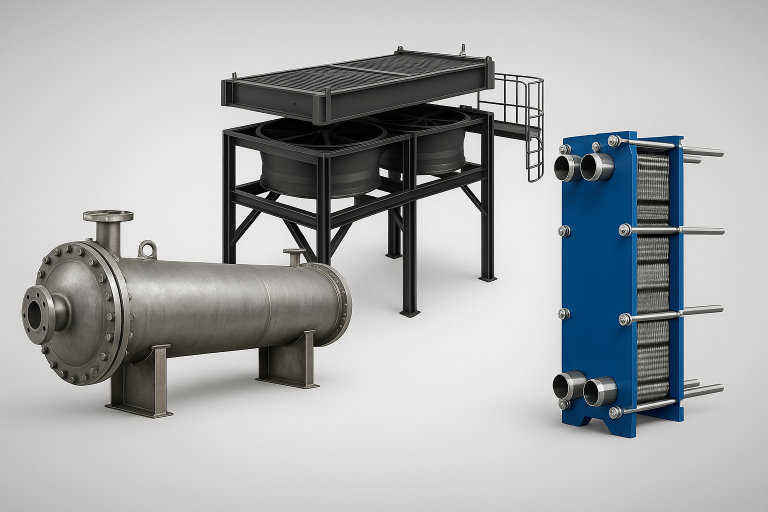

Both Shell and Tube Heat Exchangers (S&T) and Air Cooled Heat Exchangers (ACHE) are widely used in industries such as petrochemical plants, oil refineries, and power generation. Although both serve the same purpose—transferring heat between process fluids—they operate differently and offer unique advantages and limitations.

1. Working Principle

-

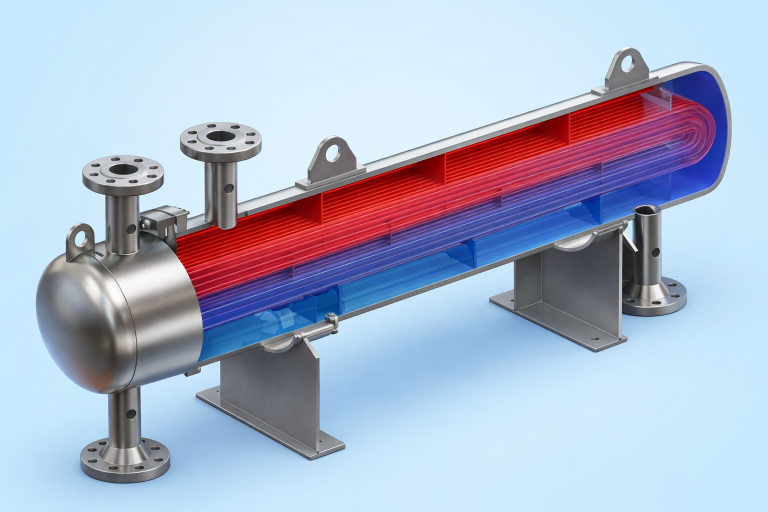

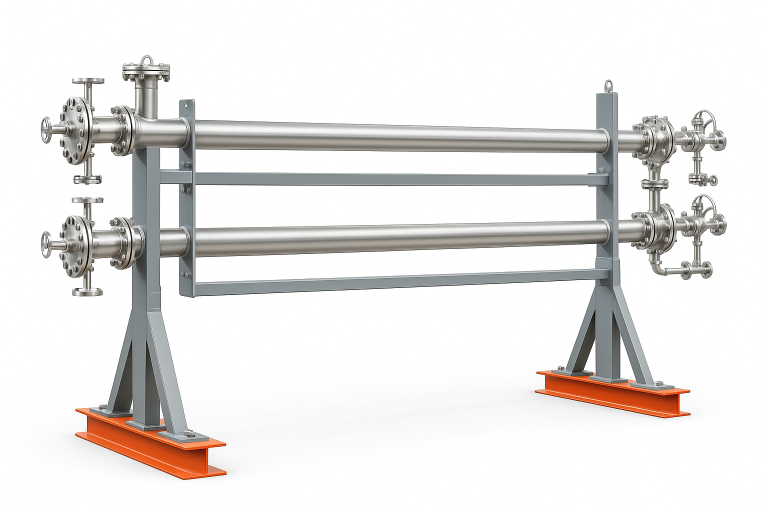

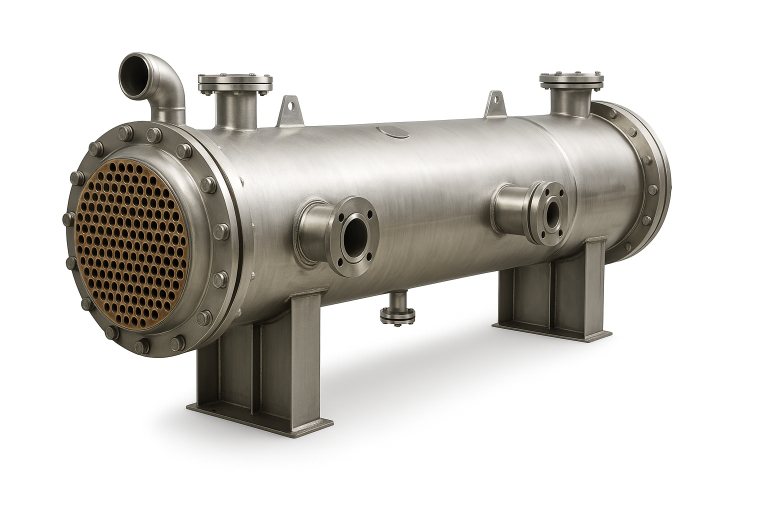

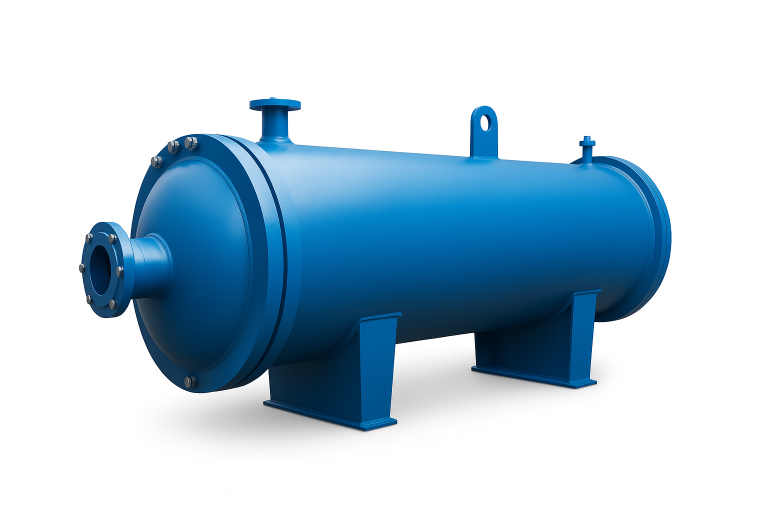

S&T Heat Exchanger

Utilizes two process fluids that exchange heat through the tube walls. One fluid flows inside the tubes (tube side), while the other flows around the tubes (shell side). This design is suitable for liquid-to-liquid or liquid-to-steam heat transfer. -

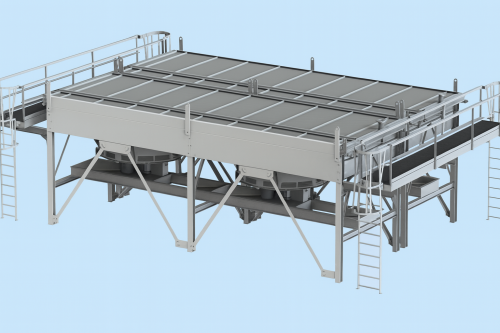

Air Cooled Heat Exchanger (ACHE)

Uses ambient air to cool process fluids instead of water. The hot process fluid flows through finned tubes, and fans force or induce airflow across the fins, transferring heat to the atmosphere.

2. Advantages and Limitations

S&T Heat Exchanger

Advantages:

-

Handles high pressure and high temperature applications

-

Suitable for phase changes (condensation or boiling)

-

Compact design fits limited space installations

Limitations:

-

Requires cooling water, adding to operational costs

-

Needs corrosion control and regular cleaning to prevent fouling

Air Cooled Heat Exchanger

Advantages:

-

Eliminates water usage, ideal for arid or remote locations

-

Lower maintenance costs due to no water treatment system

-

Environmentally friendly with minimal water discharge

Limitations:

-

Larger footprint required for installation

-

Efficiency depends on ambient air temperature

-

Higher initial cost in some cases compared to S&T exchangers

3. Application Selection

Shell and Tube vs Air Cooled Heat Exchanger

-

Choose S&T Heat Exchanger when dealing with high-pressure, high-temperature processes or limited space.

-

Choose Air Cooled Heat Exchanger when water conservation is critical, environmental impact must be minimized, or the site is located in a remote area.

Conclusion:

Each type of heat exchanger has specific strengths. Selecting the right type depends on process requirements, environmental conditions, and cost considerations to ensure optimal efficiency and reliability.

📩 Contact Us Today

📩 Email: jimmy@hesco.co.th

📞 Phone: +66 983282941