A Heat Exchanger is a device designed to transfer heat between two fluids (liquids or gases) without allowing them to mix directly. The primary purpose is to increase or decrease the temperature of one fluid by utilizing the heat from another. This process improves energy efficiency and reduces operating costs in various industrial applications.

Why Are Heat Exchangers Important?

-

Energy Efficiency: Recovers excess heat and reduces overall energy consumption.

-

Improved Process Performance: Provides stable temperature control in production systems.

-

High Flexibility: Can be used with different types of fluids, including liquids, gases, or mixtures.

-

Versatile Applications: Commonly found in power generation, petrochemical plants, food processing, and HVAC systems.

Common Types of Heat Exchangers

-

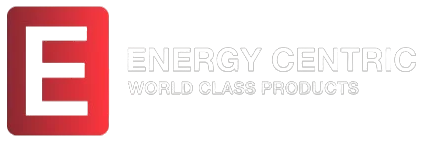

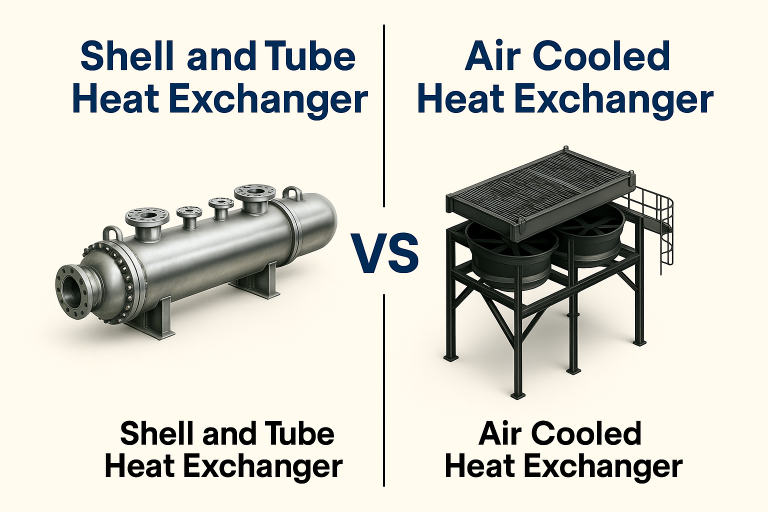

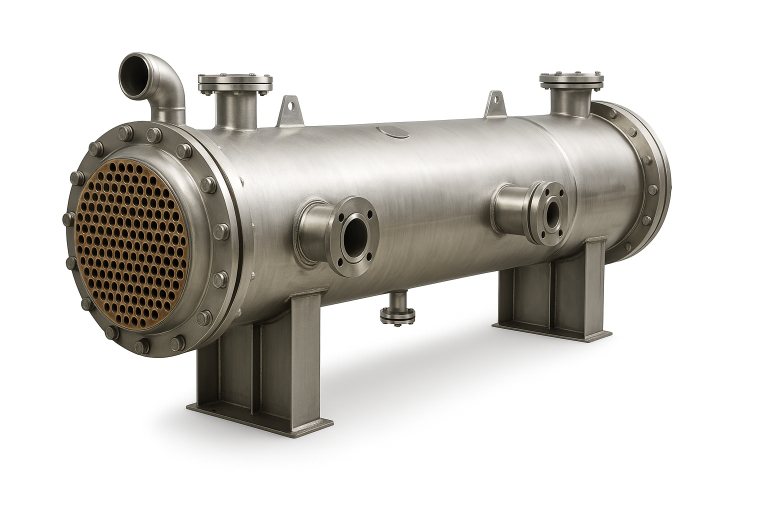

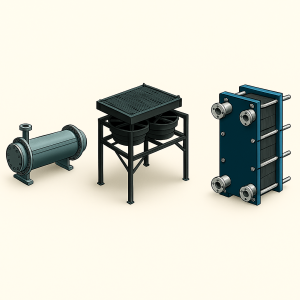

Shell and Tube Heat Exchanger – Features multiple tubes housed inside a shell; ideal for high-pressure and high-temperature applications.

-

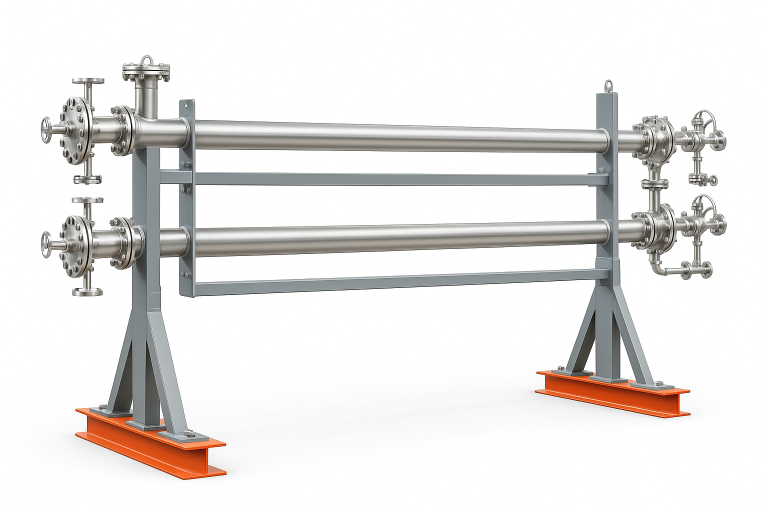

Air Cooled Heat Exchanger (Fin Fan) – Uses ambient air for cooling, eliminating water usage; suitable for arid or remote locations.

-

Plate Heat Exchanger – Consists of multiple thin plates stacked together; offers high heat transfer efficiency in a compact design.

-

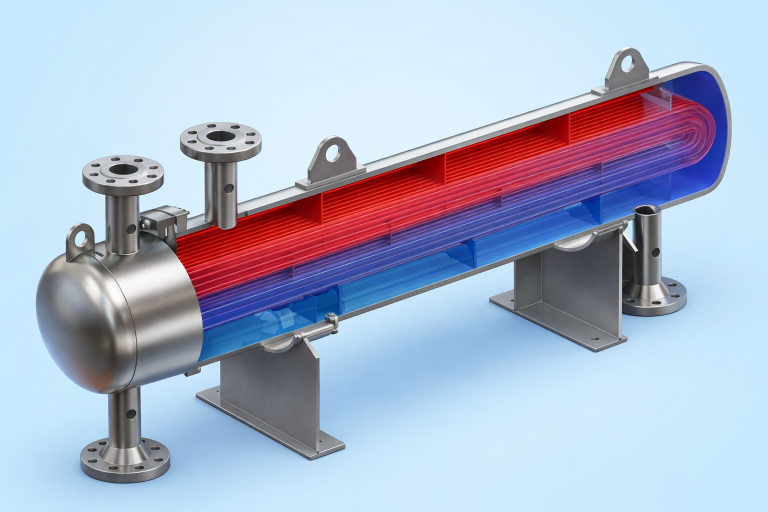

Double Pipe Heat Exchanger – Simple construction; suitable for small-scale operations or single-stream processes.

Industrial Applications

-

Oil & Gas Refineries: Heat transfer during distillation and process cooling.

-

Power Plants: Temperature control in turbines and steam systems.

-

Food & Beverage Industry: Pasteurization and cooling processes.

-

HVAC Systems: Heating and cooling for buildings and industrial spaces

🔧 How Does a Heat Exchanger Work?

At its core, a heat exchanger enables thermal energy exchange between two fluids at different temperatures. These fluids are typically separated by a solid wall to prevent mixing, yet allow efficient heat conduction. Depending on the type of exchanger, the heat transfer can happen via conduction, convection, or both.

There are three common flow configurations:

-

Counterflow: Fluids move in opposite directions — provides the highest thermal efficiency.

-

Parallel Flow: Fluids move in the same direction — easier to construct but less efficient.

-

Crossflow: Fluids move perpendicular to each other — used in compact designs like finned air-cooled systems.

🌡️ Materials and Durability

The materials used in heat exchangers depend on the fluid properties, pressure, temperature, and corrosiveness. Common materials include:

-

Carbon steel and stainless steel

-

Titanium and copper alloys for corrosive environments

-

Graphite or polymer materials for chemical resistance

Proper material selection ensures long service life, reduced corrosion, and improved thermal performance.

🛡️ Safety and Compliance

Heat exchangers that operate under high pressure or temperature must comply with international standards, such as:

-

ASME Section VIII for pressure vessels

-

TEMA (Tubular Exchanger Manufacturers Association) standards

-

API 661 for air-cooled heat exchangers

These codes guarantee structural integrity, safe operation, and quality assurance.

📈 Maintenance and Monitoring

To ensure long-term performance, heat exchangers should undergo routine inspections and maintenance:

-

Cleaning to remove scale, fouling, and sediment buildup

-

Thermal performance monitoring via temperature and pressure sensors

-

Non-destructive testing (NDT) for cracks or corrosion

Regular maintenance helps minimize unplanned shutdowns and increases equipment lifespan.

📞 Contact Us for Expert Heat Exchanger Solutions

At HESCO (Thailand), we specialize in the design and fabrication of high-quality Shell & Tube, Air Cooled, and Plate Type Heat Exchangers — fully compliant with international standards like ASME and TEMA.

Whether you’re looking for guidance on heat exchanger selection or custom fabrication for your industry, our engineers are here to help.

👉 Get in touch with us today!

📩 Email: jimmy@hesco.co.th

📞 Phone: +66 983282941